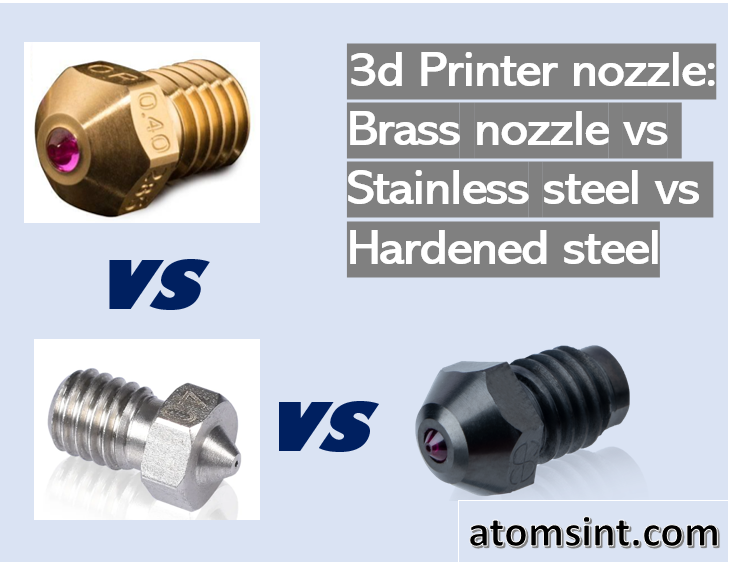

So, You have purchased a 3D printer which comes with brass nozzle and your printer’s nozzle is beginning to wear down, which is having a bad impact on the print quality—even to the point where your first layers won’t adhere down effectively.

The factory nozzle that came with your new 3D printer may not be something you like. Now that you have a selection of nozzles to choose from, you want to know which one would work best.

To help you in selecting a nozzle and to outline the key distinctions between the options, I’ve decided to write this blog post which might be of guiding points. Mostly, Nozzles come in brass, stainless steel, and brass.

Brass is the most optimal nozzle due to its high thermal conductivity and this is the basic in 3D printing.

The quick answer is that, if you are printing non-abrasive filaments, Brass is probably going to give you the best nozzle for your prints. Stainless steel is the ideal material to use if you want to print parts that are suitable for use in food or medicine. The best material to use to print with abrasive filament is Hardened Steel.

Continue reading to learn more about this subject and to gain useful information that will aid your 3D printing endeavors.

I have listed some of the most useful and best tools for your 3D Printers, You can check them here in this Amazon link

Brass nozzle

If you’re looking for a brass nozzle to purchase, we would recommend this LUTER 24-Piece Brass Nozzle Set.

There is a very solid reason why most 3D printers come with a brass nozzle.

Because brass has excellent thermal conductivity, heat is transferred from your heater block to the nozzle and then to the filament considerably more effectively than it is with other nozzle materials.

However, brass nozzle has some limitations, which is why various nozzle materials have been created in the field of 3D printing.

Because brass is a relatively soft metal, it can wear down and harm your nozzles if it scratches the bed or if you print with abrasive filament.

I have noticed that frequently there is a formation of ridges and grooves on the inner surface of the nozzle, which can block the hole or enlarge it to the point where it is no longer functional.

Brass nozzles are not only less expensive, but they are also simpler to machine and produce.

Practically speaking, unless you are printing with abrasive filament, there is no real benefit to utilizing a stainless-steel nozzle.

Majority of the 3D printers use non-abrasive materials like PLA, ABS, or comparable ones when they produce objects.

In these situations, a perfect brass nozzle will serve you well, however you might want to upgrade from some of the factory brass nozzles that came with your 3D printer.

Stainless Steel nozzle

So, you’re looking for a stainless steel nozzle to purchase? We would recommend this kit which comes with 20 PCs USPacific Stainless Steel Nozzles with Needle Cleaning Kit, and 4 nozzles with a Ø0.4mm

One more common nozzle material you’ll find most people utilizing is stainless steel. Its key advantage over brass nozzles is that it is more wear resistant.

Even though it has improved wear resistance, it isn’t the greatest available.

Nozzles made of stainless steel perform a fantastic job of resisting wear from abrasive filaments.

Due to their tendency for heating inefficiently, responding slowly to retraction, and maybe clogging more, they can be frustrating to print with.

Check my article on How to Unclog & Prevent Clogging in Your 3D Printer for more information.

Usually, if you fine-tune your settings, there shouldn’t be too much of a problem.

Stainless steel nozzles’ key distinguishing characteristic is its capacity to keep the nozzle cleaner than most other nozzles by preventing filament from covering it.

A stainless steel nozzle could look nicer, but unless it’s for abrasive filament, I wouldn’t think of it as an enhancement.

Stainless steel nozzles can be used with virtually any material.

The food-safe and medical-grade qualities of stainless steel are its other key advantages over other nozzles.

It has been acknowledged by the FDA as being food-safe, thus it can be used with safety in situations where food will be involved. This advantage is not shared by other nozzles.

It can print with abrasive materials, however Hardened Steel is more appropriate for this.

Hardened Steel nozzle

The next level up from stainless steel nozzles in terms of wear resistance is hardened steel.

This is just plain steel that has been specifically treated to be incredibly wear-resistant. With heavy use, it can last users up to 24 months.

However, when planning to print with abrasive filament, you should use hardened steel nozzles.

With tougher metals, it is challenging to achieve a smooth internal surface because of the way nozzles are made.

To extrude evenly, it is preferable to have a smooth inside. Hardened Steel does not meet those requirements perfectly, but not to the point where it cannot still produce prints of excellent quality.

The GO-3D Hardened Steel Nozzle from Amazon is what I’d recommend. They are highly regarded, resistant to abrasion and corrosion, and compatible with the majority of 3D printers that use an M6 thread, such as the Ender 3.

Thermal Conductivity

Brass has the best thermal conductivity, as we already discussed earlier in this article which makes it easier to print with.

Because there is less of a temperature difference between the nozzle and the thermistor, brass nozzles can melt filament more quickly and at lower temperatures.

Stainless steel and hardened steel have decent thermal conductivities, but you might need to tweak your temperature settings to achieve the best results. Achieving this optimal setting will take some trial and error to arrive at that point.

Pro Tip: Additionally, you can turn down your cooling fans to give your material more time to fully harden before the next layer is extruded.

It will require some trial and error before you find your optimum settings, but it shouldn’t cause you any problems.

For instance, Steel nozzles may not heat up or maintain the necessary heat as rapidly as you would like for some materials.

To print higher-temperature materials, it’s a good idea to utilize a highly thermally conductive metal, but it’s not necessary.

When it comes to heat conductivity, stainless steel nozzles fall short to the point where your printing can be impacted. Even while these nozzles have much better levels of abrasion resistance than brass, they are nevertheless susceptible to highly abrasive filaments like carbon fiber.

Here, you should choose a nozzle made of hardened steel at the very least. They also have far greater heat conductivity in addition to having much higher abrasion resistance.

It essentially implies that it takes longer for the nozzle to reach a high temperature and that it may struggle to keep it there, particularly when using fast printing speeds and cooling fans.

Although you may occasionally make up for this by printing more slowly, the filament may not flow out as well as it should, which would be a sign of this poorer thermal conductivity. Ideally, you should only use stainless and hardened steel nozzles when absolutely essential.

Endurance of the Nozzle

Hardened steel, stainless steel, and brass are the three materials that make up the most resilient and long-lasting nozzles. Some individuals only use hardened steel nozzles while printing, and it easily lasts them more than a year.

It’s a wise choice to switch to Hardened Steel if you don’t enjoy the trouble of frequently changing nozzles after printing with abrasive filaments. Some users have been getting excellent results after using their Hardened Steel nozzle for multiple spools of Nylon X (a extremely abrasive material).

This helps highlight the materials’ resilience and resistance to wear. Be careful of the potential print performance trade-offs depending on the materials you are printing.

Although typical stainless-steel nozzles are significantly softer than hardened steel and more likely to withstand abrasive filament, they are harder than brass.

Type of material for the Nozzle

Stainless steel vs Brass nozzle:

Brass

- PLA

- ABS

- PETG

- HIPS

- Nylon

- TPE

Stainless Steel

- NylonX

- Carbon fiber

- Some filaments such as wood-filled, wax-filled or ceramic filled

- Metal filaments like steel-filled, iron-filled, or brass-filled

- Glow-in-the-dark filaments

- Metal filaments

Hardened Steel

Similar to stainless steel nozzle however much enhanced

Alas, Which material nozzle to buy?

For day-to-day use, 3D printer users typically choose brass, hardened steel, or plated copper nozzles.

The last thing you want to do if you decide to use a hardened steel nozzle is to buy a copy version, a low-quality one. There is a pricing difference since it is much more difficult to produce these steel nozzles than regular brass nozzles.

By choosing the less expensive option, you run the risk of encountering easily avoidable printing issues because these nozzles are more likely to be subpar made, with rough finishes and nozzle holes that aren’t drilled through the center. You should use an authentic E3D nozzle or a reputable source to avoid any potential extrusion issues.

Hardened Steel Nozzle

After researching all about the nozzles available in the market, I would suggest GO-3D Hardened Steel Nozzle from Amazon for your hardened steel nozzles. Since, It has excellent quality control, receives good ratings, and just completes the task at hand. Spend no time or energy experimenting with nozzles that are inexpensive, and mass made.

It always suggested to go for high quality nozzles for seamless to minimize flaws and reduce troubleshooting time.

Plated Copper Nozzle

The Genuine E3D V6 Plated Copper Nozzle is one of the nozzles that I haven’t yet discussed but is a really dependable item that performs the task admirably. Your printing quality and usability should significantly improve with this nozzle.

Due to its incredible thermal conductivity, copper is employed and thrives in situations where sustaining a high temperature is crucial.

With this nozzle, many individuals claim they have no longer had clogs, and it is reasonably priced. One of the nicest features is how materials are far less likely to adhere to the nozzle, requiring less upkeep and allowing for longer printing sessions. More smoothly than your typical brass nozzles, it extrudes plastics.

Conclusion:

To put it in a nutshell, the nozzle you want to select can always depend on the type of filament you’re printing and your production schedule. While the machine makers always send us Brass nozzle, you can select your own.

After going through this article, there are many methods in selecting a nozzle, for example, stainless steel vs brass nozzle, however, it shouldn’t be complicated. Few nozzles are applied for selected materials, while others can be used as a common nozzle for most of the materials. Since you know the key differences and applications, selecting the nozzle is pretty simple.

Pro Tip: You can also look for Micro Swiss plated brass nozzle and Tungsten based nozzle