Germany-based software start-up 1000 Kelvin and 3D printing giant EOS have collaboratively announced the integration of AMAIZE in their software platform.

1000 Kelvin has announced the integration of AMAIZE, the first AI co-pilot for AM with EOS to dramatically increase productivity and accelerate engineering speed.

What does 1000 Kelvin do?

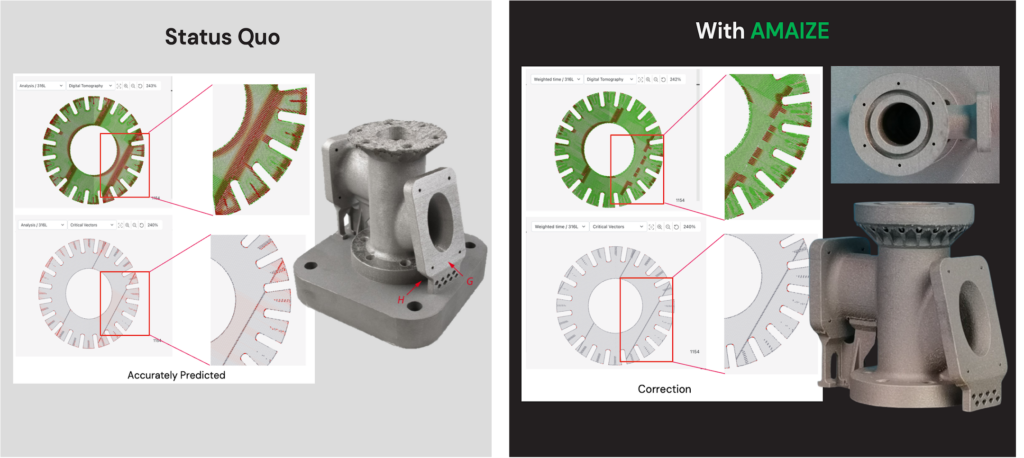

1000 Kelvin helps companies improve the produce faster parts with first-time-right and reduced print defects. This is possible by their AI model that enables end users to effectively produce parts by additive manufacturing. Learn more at www.1000kelvin.com.

What does the EOS & 1000 Kelvin collaboration mean?

This integration in EOSPRINT aims to optimize production workflows and improve engineering processes across industries such as aerospace, energy, and contract manufacturing. By leveraging AI technology, clients can expect to streamline their design processes, potentially leading to a reduction in engineering costs of up to 80%.

Omar Fergani, CEO of 1000 Kelvin, said, “The integration with EOS software is a testament to the open architecture of EOS products and the extensive resources of the EOS Developer Network (EDN). These factors have allowed us to seamlessly incorporate the EOSPRINT APIs into our platform, ensuring that our customers can effortlessly benefit from the combined strengths of our technologies.”

AI-Copilot AMAIZE

FKM, a European AM contract manufacturer, was one of the early adopters of AMAIZE and they have received positive feedback on reduced print errors and improved quality in product.

Martin Steuer, Senior Vice President of EOS’s Software Division, has spoken about the effect of AMAIZE’s AI predictive capabilities in facilitating a shift from physical to digital iteration and advancing the industrialization of additive manufacturing.

Matthias Henkel, CEO of FKM, added, “1000Kelvin’s AMAIZE aligns perfectly with our commitment to digital excellence in manufacturing. It allows our engineers to predictively navigate complex components quality and consistency requirements.”

1000Kelvin made their debut in Formnext 2023, AMAIZE also optimizes 3D print recipes, reducing the need for costly iterations and simulations.

One of the case studies provided by the company included a rocket launch provider in California who overcame print failures with AMAIZE, achieving better quality and cost savings. Notably, AMAIZE enabled an 80% reduction in support structures, slashing overall costs by over 30% and accelerating time to market.

AMAIZE has also partnered with Fieldmade which deploys 3D Printers in military zones to effectively keep combat readiness.

The current Market in 3D Printing needs a lot of start-ups like 1000 Kelvin that innovate and bring new paradigm shifts in the Metal 3D Printing industry.