We all know the professional work of Youtuber stefan aka cnc kitchen. Most of his works are scientifically backed by detailed iterations of experiments. His channels provides insights to a detailed level and much interesting topics in the trending field of 3D Printing. Once such topic was transparent jobs out of FDM printers.

We all know that whenever we hear “transparent” we tend to go for resin printing. Also, we have come across cooling 3d print and how to 3d print transparent with resin printing. However, the odor and the finish of resin printing is still limited with transparency part. There was a recent study made for ultra fast opaque resin 3d printing.

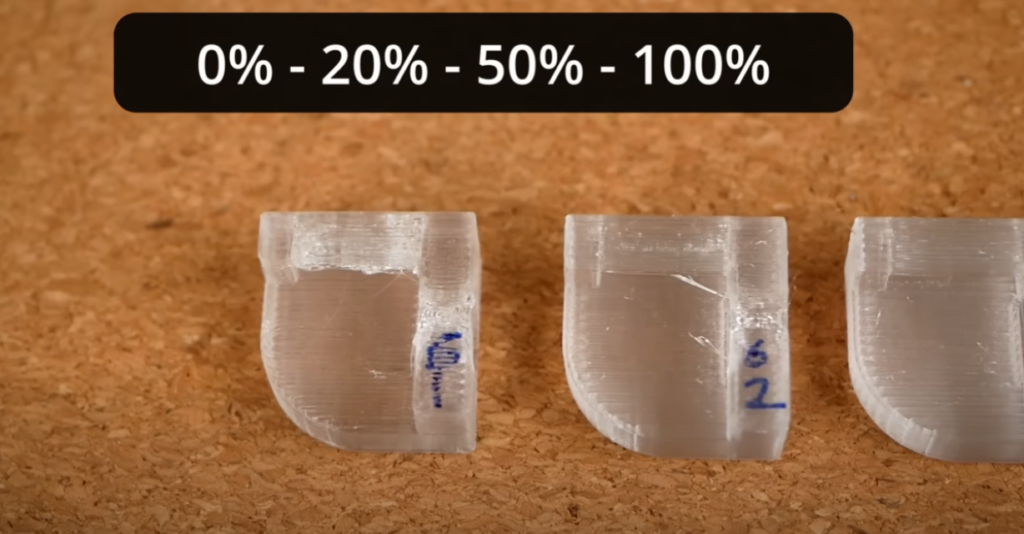

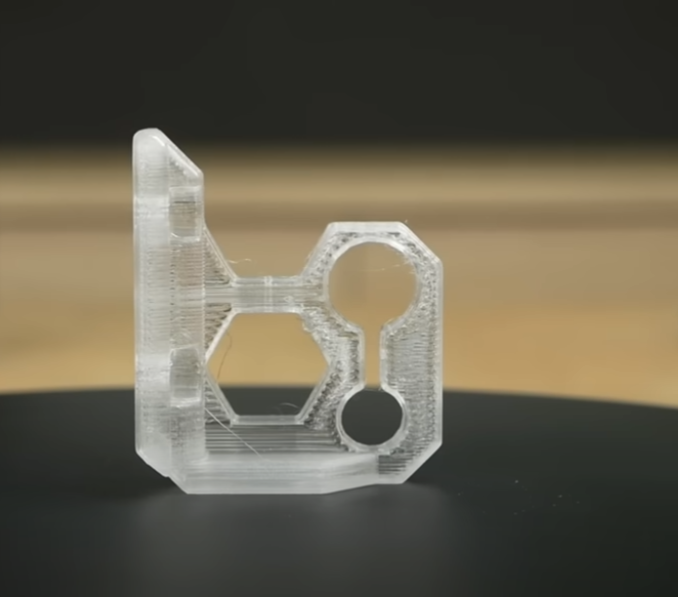

In his recent video, we can see testing the strength of FDM transparent printed part. There are a set of parameters tweaked for particular printer. This might vary with different printers and different settings. One such experiment is done with printing without any bottom and top layers. These are mainly printed with entirely infills, this kind of opens up the topic on How to 3D print transparent parts

Filaments from different manufacturers will differ differently and manufacturers tend to make a generic filament, also your machine might react in different way.

There were some good results using PCTG, but because it isn’t as common as PETG, he used that more common material in his tests. The tests were systematic and show the impact different slicer parameters have on the finished product.

Also, some interesting facts is that same slicer parameters resulted in stronger transparent parts. For more information you can check his video here.

If you’re interested you can have a look at our SLAvsSLS process and other interesting topics here.

Do let us know what do you think about this Transparent FDM printing, in the comments below.