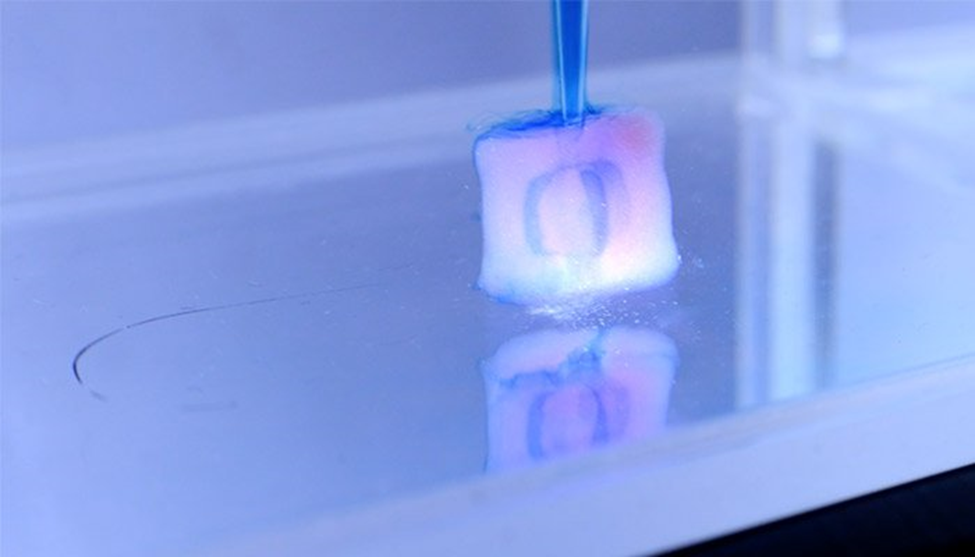

At EPFL in Switzerland, engineers from the Laboratory of Applied Photonic Devices (LAPD) have developed a resin 3D printer capable of designing objects in a few seconds. Based on volumetric printing technology, it can produce parts with an opaque resin, which until now was not possible with this type of method.

A team of EPFL engineers has developed a 3D-printing method that uses light to make objects out of opaque resin in a matter of seconds. Their breakthrough could have promising applications in the biomedical industry, such as to make artificial arteries

Innovations focusing on the resin processes are plenty and already 5 years ago, the same team of engineers has developed a technology to considerably improve the printing speed. Usually, it takes several hours to obtain a final part and many manufacturers are looking to smartly improve the printing speed of their machines. In this specific case, they depend on the volumetric method to do so.

Christophe Moser, professor at EPFL, explained how it works: “We pour the resin into a container and spin it. Then we shine a light on the container at different angles, causing the resin to solidify wherever the accumulated energy in the resin exceeds a given level. It’s a very precise method and can produce objects at the same resolution as existing 3D-printing techniques.”

In addition to obtaining a part with a good resolution, the process is considerably faster. In fact, the engineers tested their method and successfully printed a tiny Yoda in only 20 seconds.

But what is particularly interesting is the material used: an opaque resin. The use of such a resin in a volumetric process poses a major challenge. Light does not propagate smoothly, which reduces the amount of energy needed to solidify the liquid resin. As a result, the resolution drops, which makes volumetric printing less attractive to many users. Engineers, therefore, sought a solution to circumvent this challenge and ensure that the light could pass through the resin in a straight line.

The first step was to study the trajectory of this light with a video camera. Then, they relied on computer calculations to compose the distortion of the rays. The 3D printer was next programmed to perform these calculations and correct the trajectory of the light during the printing process. The objective is to redirect the light to the desired locations to obtain enough energy to solidify the resin.

Engineers hope to use this technique in the medical field, particularly to design artificial arteries, as these procedures often require the use of opaque resin. The next steps will be to use several materials at the same time and to increase the resolution from a tenth of a millimeter to a micrometer. We will keep you informed about any upcoming developments in the project! In the meantime, you can find more information HERE.

What do you think of this opaque resin 3D printing method?

Let us know in a comment below

[…] finish of resin printing is still limited with transparency part. There was a recent study made for ultra fast opaque resin 3d […]