A group of researchers from Khalifa University, UAE have developed material to 3D print a unique optical sensor that can illuminate and sense temperature, at the same time keeping its strong structural behavior in extreme conditions.

Optical sensors are widely used in farming, chemical engineering, medical diagnostics, power generation, and pipelines. These sensors are well developed and largely used in many areas, however, they are vulnerable to giving faulty readings in rugged conditions.

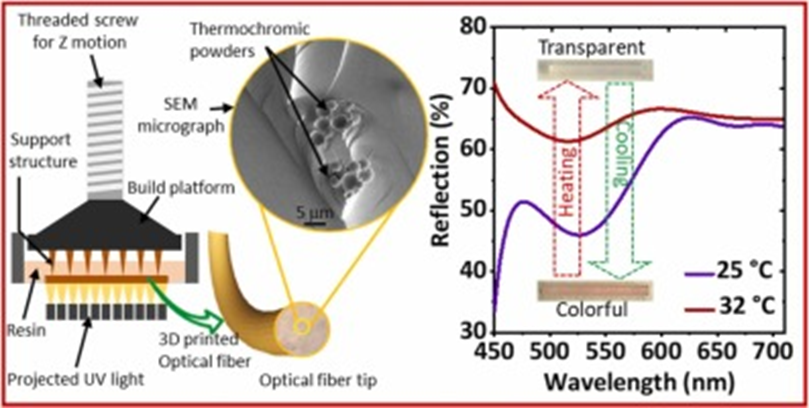

The research team has developed a polymer-based optical fiber that be 3D Printed to accurately measure temperatures and they have published their results in science direct. Credit goes to the team,

Credit to the Researchers:

Dr. Haider Butt, Associate Professor of Mechanical Engineering, Dr. Fahad Alam, Postdoctoral Fellow, Dr. Mohamed Elsherif, Postdoctoral Fellow, and Ahmed Salih, Research Assistant.

The results can be found here…

Cost Effective, Reusable, and Thermochromic:

These optical fibers can be operated in a broad temperature range, and they do not need any electric cables. They are easily resistant to magnetic and electric fields.

“Optical fiber sensors can work in harsh environments as they are immune to electromagnetic interferences and have remote sensing capabilities,” Dr. Butt said.

“They show high sensitivity but they do have durability issues and are prone to be affected by small mechanical disturbances. Polymer fiber-based sensors could be an alternative solution because of their robust strength and efficiency. They are also unaffected by ambient disturbances. Polymer-based fibers exhibit low sensitivity, but they are relatively accurate and reusable.

Type of measure: Thermochromic

Researchers chose the Thermochromic method to measure the temperature, However, it optical sensors can measure by different ways. They chose to chose to focus on the thermochromic method, producing fibers doped with reversible thermochromic powders to show a temperature-dependent optical response.

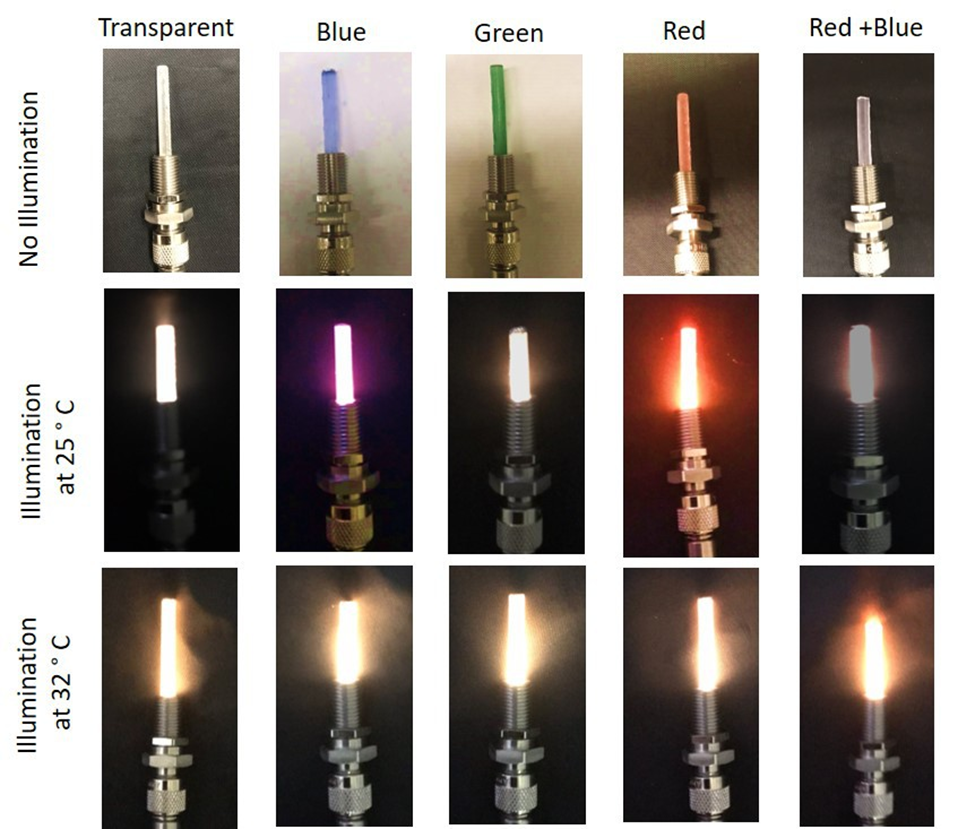

Dr. Butt said. “At room temperature, all the colors were distinguishable, but at 32 C, all samples turned transparent and were indistinguishable. This effect was reversible as the color came back when the optical fibers were cooled to room temperature again. We did this multiple times to ensure the repeatability and longevity of the thermochromic powders in the fibers.”

In the room temperatures of 24-25C the colors were clearly visible and when it went to 32C it was transparent and they could notice the difference. Even though the difference is quite small, this is quite remarkable keeping in mind the great potential in sensing applications for 3D-printed optical fibers.

You can also find some of the research papers in similar niche here, where some researchers developed a 3D printing complex glassomer parts at a microscopic scale.